Boot from 1999

Shaft cleaned up well wire bench grinder wire wheel

More corrosion hiding under the boot

I cleaned and painted an end to see what it would look like.

I took the first boot off to replace it

A little hidden surface corrosion underneath the seal

Here is the CV joint itself. Very little wear noted

I used some electrox primer I had

Then black enamel

Time to get the new boot on. I bought a boot stretching cone

Warmed the boot in hot water to make it flexible

Lots of soapy water and tried to get it on the cone.

I failed miserably. My research suggested this was the way to do it but I think the boot I bought was not a stretch boot. I looked into how to get the driveshaft end off. Turns out its relatively easy. A tap in the right place with a hammer and off it popped.

Driveshaft end off the shaft. It is held on by a small clip in the groove you see on the shaft. The tap compresses the ring and allows the end to pop off.

Different type of joint here. This one takes up horizontal play as the wheel moves.

Shaft with just the one end attached

I dismantled the first joint to clean and inspect it. Very well engineered thing a CV joint.

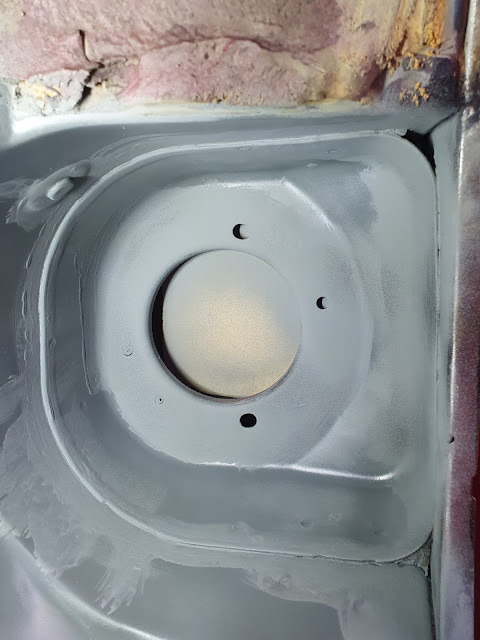

Bare joint. Ignore the random paint stuck to the outside. I removed this later.

Painting the second end.

Decided the re-do the first end as I damaged the paint in my removal.

All painted and ready to go.

Painted shaft, ends and new boots ready for assembly

Boot on first joint

Second Boot on shaft

Some new Grease

Joint rebuilt and ready to go on shaft

Back on shaft and greased up.

Turned around to fit boot.

Fitted ready for clamp

Clamp fittted.

The clamp gives a nice tight fit.

Refurbished verses non refurbished. Ignore the missing boot clamp. I had to order some of the right size.

Finished driveshaft (including final clamp)

Gearbox side.

Hub Side.

Whilst I could have probably purchased a couple of refurbished shafts for not a lot of money, there is no fun in that! I probably spent about £20 on this ignoring the tools I bought. Still got the other one to do yet.

Thats it for tonight.

James